Noom’s Sustainable Agriculture & Production Quality Standards

Noom farming focuses on comprehensive ecosystem regeneration, operating according to the natural life cycles of all things. Even some fertilizers or additives approved under organic standards are strictly prohibited at Noom farms and production facilities.

Noom operates under a philosophy of sharing difficulties and benefits with a community group to regenerate the natural environment and preserve local culture. To ensure transparent original quality and ecological fair-share in each product, Noom affirms its core values, operating principles and close connections from farmers to dealers to customers.

We consistently uphold quality standards in sustainable agriculture and food production

I. Agricultural Standards

1. Agricultural land

- Designated agricultural land per Vietnamese law, layouts following legal requirements for land use and management by local authorities.

- Soil safety and nutrition certified by authorized agencies before cultivation.

- Farm models and operations suiting local farmers’ resources and indigenous knowledge. Designs respecting local customs, culture and regulations.

- Best farms have multi-tiered ecological hedgerows. However, we also adjust based on local government conditions allowed. Isolation ditches and drainage filter residuals from outside environment. Anti-seepage berms and hedgerows prevent outside waste and chemicals while sheltering and conserving flora, fauna and aquatic life, increasing on-farm biodiversity.

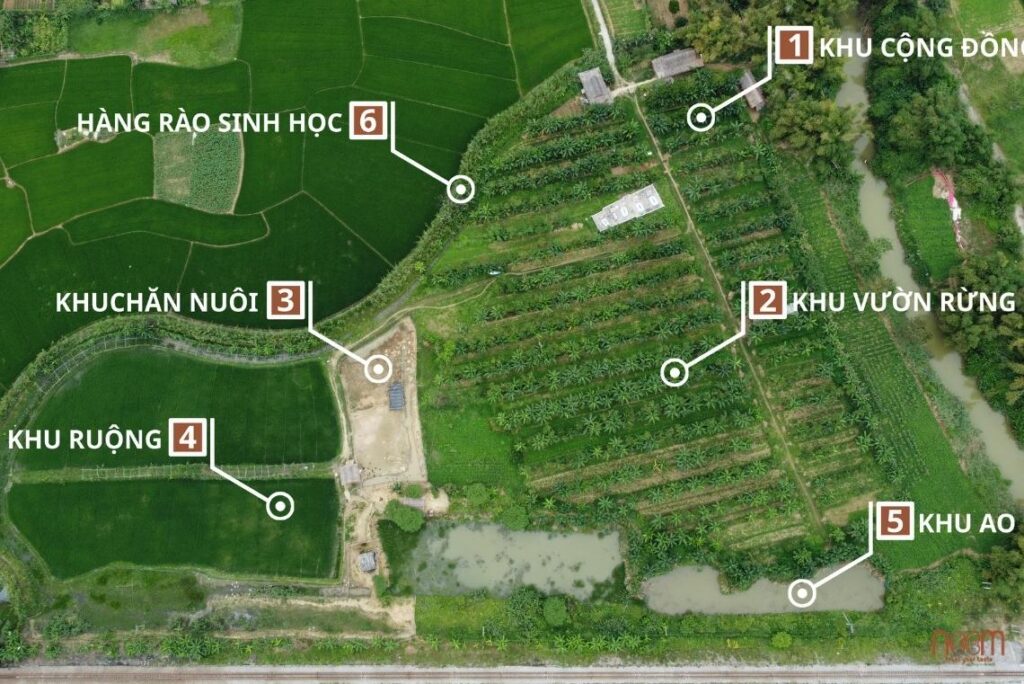

Figure 1

2. Soil nutrition and crop care

- Prioritize closed nutrient and energy cycles.

- Control stocking density and scale for each ecosystem development stage.

- Minimize disturbance to native soil structure, digging, trenching, hoeing, plowing.

- Strictly prohibit synthetic fertilizers and pesticides.

- Do not use organic fertilizers, organic pesticides, homemade biological sprays.

- Use plant and animal materials naturally available on or near the farm.

- Prioritize cattle, buffalo, chicken manure from animals fed local organic feeds, or from nearby farms.

- Ash from burning firewood, rice husks, food prep residues.

- Limestone from oyster, clam, snail shells.

- Powdered rock phosphate in limited, judicious amounts.

- Soil nourishment via green manures, mulching, increasing organic matter.

- Maximize on-farm residues like bean pods, perilla stalks, oil press cakes to close biomass loops.

- Minimize purchase of off-farm inputs. Prioritize on-farm green manures and composts.

- Animal manures naturally compost until fully rotted (no set months, depends on weather and materials) or composted at 1:1:1 ratios ensuring C:N of 25-30:1.

- Leave land fallow, grow cover crops, chop and drop.

3. Integrated pest and disease control

- Diverse crops with multi-tier canopies, following Forest-Garden-Pond-Livestock design principles to minimize crop risks and respect ecosystems.

- No spraying, even approved organic biological compounds to protect crops.

- Diverse crop systems:

- Pioneer trees like banana, eucalyptus, acacia.

- Short 3-5 year fruit trees, medium 5-10 year, long-term 15-35 years.

- Non-harvest forestry species 50+ years.

- Annual vegetables suiting local seasons and weather. No off-season fruit.

- Ground cover crops, pioneering plants, wild plants and bushes.

- Balance via crop diversity. Mechanical traps or hand-picking may be used at first before ecosystem self-balances. Only in extremely urgent cases.

- Still prioritize biodiversity, natural enemies, microbial balance with birds, snakes, dogs, cats to balance food webs in cultivation areas.

- No rodenticides or snail bait

- Weed control via:

- Manual weeding, mowing, grazing, no herbicides or burning.

- No plastic film or synthetic mulches, even biodegradable plastic films.

4. Crop seeds

- Native landrace, open-pollinated seeds, saved for future seasons. Must be varieties traditionally grown and seed-saved by local people.

- No F1 hybrids, genetically engineered or unapproved exotic imports.

- No seed treatments except natural on-farm materials like ash, lime, perilla, chili, ginger, garlic.

- No purchase from industrial producers. On-farm saving of native seeds is top priority.

- Prioritize seed-raised over grafted planting material. Grafts used in properly calculated proportions to seedlings, focused on 100-year sustainability.

5. Animal breeds

- Poultry:

- Native breeds.

- No genetically selected breeds for eggs, meat or high production.

- Livestock:

- Native breeds.

- No genetic selection or created hybrids.

- No GMOs.

6. Animal feeds

- Prioritize organic feeds from the cultivation area itself. Feeds include pasture, fodder and grains produced on-site or nearby to minimize transport.

- Require purebred feeds, no hybrids/GMOs with genetic risks.

- Strictly prohibit hormones, antibiotics, vaccines, synthetic dewormers, pharmaceuticals for growth promotion or disease treatment except legally required outbreak spraying.

- Strictly prohibit commercial, even organic, feeds.

- Precise feed ratios recorded, with on-farm or local sources.

- Balanced nutrition including vitamins, minerals, protein, amino acids, fats, energy and fiber.

- Shaded, clean housing and water, with sun exposure, room for foraging. No foul odors or disease vectors in livestock areas. Waste flows to fields.

- Livestock live comfortably, not aggressive or stressed. Able to wallow, forage naturally.

- Over 5000 sqm of space for livestock, aquaculture:

- Fish ponds 2500 sqm

- Cattle: 700 sqm

- Pigs: 500 sqm

- Chickens: 500 sqm

- Ducks: 1500 sqm

7. Cultivation and production water

- In cultivation, natural water from rivers and streams filtered naturally via ecological hedgerows. Tested for safety before use.

- In production, deep well water filtered through sand, manganese, activated charcoal, coconut fiber and reverse osmosis.

Large ditches around farm perimeter filter

Large ditches around farm perimeter filter

2. Ingredients used

- Raw sea salt from salt fields using traditional concentration methods passed down for generations in Vietnam

- Noom crude sugarcane sugar, 100% sugarcane juice concentrated using traditional sugarcane cooking processes handed down for hundreds of years, ensuring VSANTP standards.

- Cold mechanically pressed oil, not refined, not heat treated or only very mildly heat treated.

- Plant spices naturally available on noom farms.

- Fish sauce fermented by noom from raw sea salt and ocean fish.

3. Storage

- Ingredients stored in natural dry warehouses, tightly sealed and wrapped to prevent dampness

- Warehouse mold prevention through periodic smoke treatments

See section 7 for substances not used in production or storage

4. Packaging

- All bottling and packaging conforms to VN food safety regulations for direct food contact.

- Absolute priority given to eco-friendly packaging like paper.

- No single use packaging

- Glass bottles/jars preferred

- Plastic cans prioritized for large volumes

- Outer bulk packaging like crates entirely wood, paper or reusable plastic.

- Glue use minimized, preferring biodegradable latex glue

5. Label printing regulations

- Only unbleached, undyed kraft paper labels, no decals. Affixed with latex glue.

- Ink-saving printing, only required label information per Decree 43/2017/ND-CP

- No ornamental prints or advertising, avoiding ink waste and soil contamination

- Priority for best selling 1-2 color prints, avoiding contamination from excess ink

III. Production facility standards

The following standards apply to the oil, sugar, incense and seed processing facilities.

1. Facility location

- Facilities constructed according to approved zoning plans

- Full certification for worker safety and food safety

- Facility grounds:

- 30% buildings, 70% green spaces

- Lots of greenery, bio-hedges, clean air, AQI under 50

- No unpleasant odors

- Far from pollution, toxicity, unaffected by environmental contaminants

- Adequate space for production lines meeting designed capacity, accommodating processes and industrial hygiene.

2. Facility layout and design

- Layout aligning production flow with wind direction to avoid contamination from boilers, wastewater treatment, waste storage, restrooms etc.

- Design flowing one way from incoming ingredients to finished products. Separate zones:

- Zone 1: ingredients/supplies warehouse

- Zone 2: ingredient cleaning/prep

- Enclosed zone: Pressing – Filtration – Bottling. Separate closed off area.

- Separate industrial hygiene (CIP), mechanical waste collection, wastewater collection preventing cross-contamination.

- Internal roads durable, dust-free. Elevated with railings, easy to monitor worker safety.

- Wastewater drainage (process, sanitary, rainwater) separate covered channels sloped for drainage, no standing water.

- Strict worker hygiene and safety protocols, separate locker and gear areas.

Structural

- Floors in production areas sloped for drainage, durable, non-porous, non-slip, easily cleaned.

- Drains and sumps have traps to prevent odors, insects and microbes from entering the facility.

Ventilation

- Ventilation windows for air circulation, heat dissipation, and venting process emissions.

- Pressing/filtration/bottling areas must have ventilation to maintain safe working temperatures.

Steam, heat and compressed air

- Steam boilers designed and built from food-grade 405 stainless steel

- Located in separate area

Wastewater, solid waste and emissions management

Solid waste

- Spent grains collected in dedicated area sized for production capacity, removed every ≤48 hrs to prevent contamination, rotting.

- Paper, labels, bottles, cans, lids, caps and other solid waste collected in proper containers in visible locations for easy collection, disposal and to avoid interfering with production.

Wastewater

- Output can sufficiently water facility greenery, no odor or chemicals.

- Wastewater treatment located separately, downwind of production areas.

- Boiler emissions do not impact production, crops or people.

No hazardous waste

Electrical

Proper certified 3-phase wiring meeting Vietnam electrical codes.

3. Warehousing

General

- Adequate capacity for production throughput

- Regular cleaning and maintenance

- Meeting all ingredient storage requirements

- Pest and rodent control

- Separate ingredient, finished goods and packaging warehouses

Finished goods

- Proper temperature and humidity for each oil type, no sunlight or direct lighting. Oils always kept in darkness after pressing.

- Full information on product, production lot, date, shift etc as required.

- Separate hold area for off-spec product awaiting disposition.

4. Ingredient prep and processing

- Ingredients stored to maintain safety and quality

- Ingredient cleaning and prep steps:

- Testing and control for pesticides, mycotoxins, heavy metals. Only conforming ingredients used.

- Removal of all soil, rocks, sand, metal and other foreign matter before pressing.

- Pressing and oil separation prevents contamination from insects, dirt, spent grains etc. Solvent residues controlled.

Decanting/bottling

- Separate area from other processing

- Equipment checks before each shift/run to ensure proper operation

- Decanting/bottling supervised to ensure product quality, safety and accuracy

Finished goods

- Lot coding by shift or production cycle, QC testing of every lot before release to ensure quality and safety

- Proper storage temperatures for each oil type, no direct sunlight. Oils always kept in darkness.

Internal transportation

- Written procedures for vehicle, storage and handling during internal transport to ensure food safety.

- No transport with chemicals or other materials that could cross-contaminate oils.

Quality control

- Separate QC area convenient for production oversight

- Equipment for basic testing of major ingredients and finished goods

- Sterile isolated micro lab

- Outside lab contracts for comprehensive testing

- Controlled sample storage and retention

Record keeping

- Full supplier records – POs, COAs, releases for traceability, QC and food safety

- Full food safety records per regulations (facility certification, product registrations etc)

5. Equipment, containers

- Containers for vegetable oils must comply with Circular 34/2011/TT-BYT dated August 30, 2011 of the Ministry of Health on national technical regulations on food safety for materials in direct contact with food.

- Direct contact with oils only stainless steel, cast iron, PET plastic. No plastic contact for heated or oil holding equipment, only stainless steel, wood, bamboo, cast iron, ceramic.

- Settling tanks made of 304 stainless steel, properly sized for settling process control for each oil type.

- Decanting/bottling/capping equipment made of 304 stainless steel. Oils arranged to prevent contamination by foreign objects or insects.

- Production equipment regularly maintained, inspected, repaired or replaced when worn or showing signs of wear.

- Testing/measurement equipment strictly calibrated and certified as required.

- Repairs and maintenance only outside production areas or during shutdowns. Thorough cleaning of equipment and surroundings follows any on-site repair or routine maintenance.

- Only food-grade lubricants used on equipment in direct contact with products.

From oil filtration, storage and bottling, Noom uses stainless steel materials to easily ensure hygiene, safety and convenience during operation

From oil filtration, storage and bottling, Noom uses stainless steel materials to easily ensure hygiene, safety and convenience during operation6. Production personnel

- Valid food safety training certificates from authorized training organizations, specifically the Quang Nam Department of Industry and Trade.

- Routine annual health checks for owners and production staff at district or higher level medical facilities. Complete medical records maintained for all personnel.

- Only healthy personnel meeting Ministry of Health requirements for direct food production hired.

- In addition to good health, production staff have a cheerful attitude, work without stress and appreciate the value of the products they make, with a sense of responsibility and self-respect for lawful quality production as if for their own family’s use.

- Personnel follow strict personal hygiene procedures, changing into appropriate protective gear before starting work.

IV. Banned substances at Noom

Although some substances are permitted under organic standards, if inconsistent with Noom’s core values, operating principles and quality standards, they remain strictly prohibited.

In agriculture and animal husbandry

| Banned substances in agriculture/animal husbandry | Notes |

| peracetic acid | Commonly used to sterilize equipment, seeds, vegetative propagation materials. |

| synthetic vitamins | Plant detox, growth promoters, root regeneration, cell regeneration (rejuvenation). Rice seed plumping, shine. Larger, sweeter fruit. |

| plant growth regulators (even if plant-derived) | Regulate plant growth and development processes. |

| ethylene gas | Pineapple flowering induction, food ripening, including organic ethylene.* Can use ripening fruit to ripen others. |

| seed treatments | Like hydrochloric acid for cottonseed delinting. |

| trichoderma or bacterial spores | Compost activators. Foliar feeds or direct root drench for disease prevention in fruit, industrial crops, vegetables and rice. |

| lignin sulfonate | Key ingredient in pesticides, carbon black, animal feeds and ceramics. |

| chelation agents | Used in solutions when plants deficient in key trace elements, causing growth inhibition in adverse conditions. |

| biodegradable plastic mulches | Used in vegetable cultivation, made from biodegradable polymers that integrate into soil. |

| magnesium sulfate | Greener leaves, better photosynthesis, prevent defoliation, promote nutrient synthesis and disease resistance, prevent soil compaction, increase yields, soil pH buffering. |

In pest and disease control

| Banned in pest/disease control | Notes |

| Copper sulfate, hydroxide, oxide, oxychloride | Organic-permitted herbicide, shrimp and snail control. No field application of sulfates. |

| Soap-based herbicides | Even for farm maintenance (roads, ditches, paths, buildings) or ornamentals. |

| Soap/ammonia animal repellents | Animal deterrents |

| Insecticides | Including insecticides or miticides. |

| ammonium carbonate | Even if only used in insect traps, no crop or soil contact. |

| boric acid | Structural pest control even without crop or organic contact. |

| peracetic acid | Bacterial leaf scorch control. |

| zinc salts of polyoxin | Organic fungal disease control. |

In cleaning, sterilization, equipment sanitation

| Banned cleaners, sterilizers, sanitizers | Notes |

| Disinfectants, sterilizers, cleaners | Including irrigation system cleaners like ethanol, isopropanol, chlorine. Even residual chlorine in crop irrigation or process water.* Except chlorinated tap water meeting Vietnam potable standards. |

| sodium carbonate peroxyhydrate | Sanitizer, cleaner, bleach, stain remover including some food applications. |

| calcium hypochlorite, chlorine dioxide, hydrochloric acid | Electrolyzed water solutions, sodium hypochlorite, hydrogen peroxide. |

| ozone gas | Even if only used for cleaning. |

| soap-based virucides | Detergent-virucidal cleaners. |

| potassium hydroxide | Precursor of most liquid and soft soaps and other potassium chemicals. |

In processing and production

| Banned in Processing & production | Notes |

| coatings including polyvinyl chloride (PVC) | Widely used in food packaging. |

| yeast extract | Flavor enhancer using natural flavors, common in food industry. |

| magnesium oxide | Widely used in wastewater treatment, water purification, pH regulation. |

| sodium silicate | Fruit and fiber processing. |

| citric acid | Microbially fermented from carbohydrates vs. self-produced vinegar. |

| agar-agar, carrageenan | Use seaweed instead. |

| animal-derived enzymes | Rennet – bovine; catalase – bovine liver; animal lipase/pancreatin/pepsin/trypsin. |

| attapulgite | Filtration aid in oil processing. |

| bentonite | Soil conditioner, moisture retention, nutrient retention; animal feed toxin absorbant, binder and pelletizer. |

| calcium chloride | Micronutrient needed in small amounts by plants. However, often linked to salinity toxicity. |

| calcium sulfate | Fertilizer and soil conditioner for deeper root growth and drought/heat tolerance. |

| NaOH | No use in food oil production or agriculture. (Only amount needed for saponification in Noom soap, no NaOH residue.) |

| nitrogen gas | To preserve oils. |

| potassium chloride products | Preservatives used in sausages, fermented meats. |

| potassium iodate | Food additive in supplements, analytical reagents, animal feeds. |

| pullulan | Bulking agent widely used in food industry. |

| sodium bicarbonate | Bacteriostatic, antifungal, pH control, leavening agent, dough stabilizer, anti-caking agent. |

| soda ash | Food additive E500 used as acidity regulator, raising agent, stabilizer. |

| tartaric acid | Antioxidant food additive E334. |

| alginic acid, ammonium bicarbonate | As leavening agents. |

| sodium acid pyrophosphate | As a leavening agent. |

| collagen casings | Often bovine-derived, used as food wrapping. |

| glycerin | For dried food preservation or vacuum packing. |

| sodium citrate | Maintains food color, prevents spoilage, improves flavor. |

| xanthan gum, even plant-derived | As food preservative or binder. |

| Commercial baking powder, organic baking powder | In baked goods, sausages, fermented meats. |

Noom takes full responsibility for the agricultural and production standards we have set and consistently applied over the years. Please feel free to contact us with any questions.

Wishing you and your family great happiness in supporting sustainable agriculture and sharing the ecological benefits of mindful consumption and daily living!

VN

VN